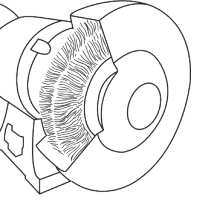

Fitting a Wheel Brush on a Bench Grinder

If you require specific information regarding fitting a wheel brush, please submit an enquiry form including any specific questions you have about the process so that one of our helpful customer service team members can assist in finding a solution. To view the Josco, Brumby and Tomcat wheel brush range, click here.

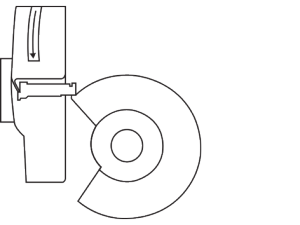

Step 1

To begin when fitting a wheel brush, remove the outer guard of the grinder.

Then remove the shaft nut and measure the shaft size.

For example, 1/2″ or 12mm, 5/8″ or 16mm, 3/4″, 7/8″ or 1″.

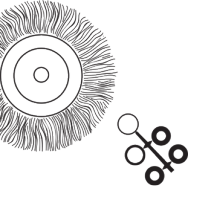

Step 2

Each Josco wheel brush is supplied with three sets of reducing bushes. Match the correct reducing bush with the diameter of your shaft, and insert it into the 1″ hole in the brush on either side. If the brush rubs against the inner guard, please refer to notes under Reducer Spacers.

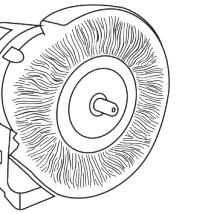

Step 3

On most bench grinders you will find that there is a thick and thin flange. The thick flange is generally fitted to the machine side of the grinder, and the thin flange is fitted to the nut side of the shaft.

Step 4

Fit your Josco wheel brush between the thick and thin flange and then tighten the nut. If there is insufficient thread to tighten the nut, please refer to notes under Reducer Spacers.

Step 5

Refit the outer guard.

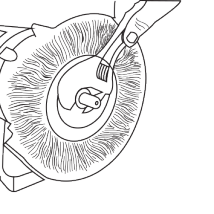

Reducer Spacers

On some machines, there may be only two thin flanges and there may not be sufficient shaft thread to tighten the shaft nut. In turn, this could cause the brush to rub against the inner guard. If this occurs, take one of the reducing bushes supplied and use the correct shaft size reducer as a spacer.

This ‘reducer spacer’ must not be mounted alongside the brush. It must always be mounted between the grinder body and the inner flange. This will enable the brush to be centralised on the shaft so that the brush does not rub against the inner guard.